Quality is the cornerstone of our company’s philosophy and a key to our global competitiveness.

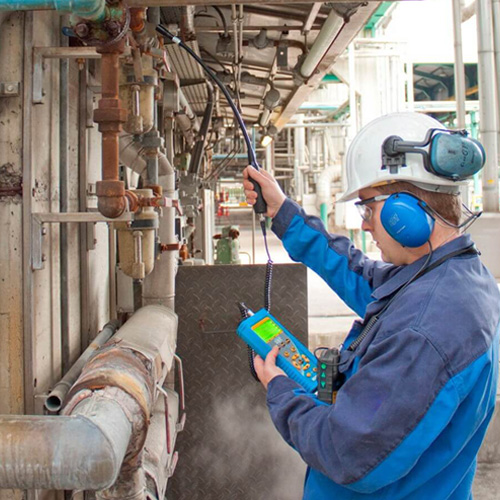

Our valves are characterised by their high quality, each one registered with an individual number for complete traceability. Both our laboratory and testing benches have the necessary equipment to carry out: test pressure (hydrostatic and pneumatic), thickness measurement, fugitive emission testing with helium, and all type of non-destructive testing.

By controlling our own resources, from development to production, from initial concept to the final solution, Sivi Kontrol remains at the forefront with design and product development.

We have developed our quality management system to meet the ever-changing market demands as well as client needs, providing new solutions jointly with our engineering department.

The purpose of the quality system is to help us improve the products and services we offer. All our facilities and processes are ISO 9001, and BS OHSAS 18001 certified as well as other important international certifications.

Sivi Kontrol has implemented and maintains a quality management system based on the requirements of ISO 9001 (2015) “quality management system requirements” for the manufacture of valves for fluid control.

The purpose of Sivi Kontrol”s quality management system is client satisfaction and fulfillment of all requirements, client’s and legal ones, as well as those necessary to assure the effectiveness of the manufacture. For that, Sivi Kontrol”s management is committed to comply with the following general targets:

- Quality management of services provided, according to international standard ISO 9001 (2015)

- Compliance with requirements agreed with our clients (product specifications, delivery time, agreed price, etc) strengthening their confidence in our company

- Compliance with other requirements: legal requirements and implicit requirements to ensure adequacy of the services provided according to client’s needs

- Continuous improvement of the efficiency of the quality management

The quality policy is spread to all staff via training seminars and via distribution of a controlled copy of the present document.

The revision of the quality policy, as well as the establishment and revision of specific quality targets, is carried out by management during system review.

- In Sivi Kontrol we are proud of our team. Our competence, work ethic and attitude towards work are outstanding. A proof of this is the frequent gratitude comments from our clients particularly regarding our level of efficiency

- Our employees are the main players when putting Sivi Kontrol business philosophy into practice

- Sivi Kontrol has outstanding and well prepared valve technicians. Not by good fortune, but by good planning.

Sivi Kontrol has established a system based on people who are successful in their effort, and whereby most of the team can carry out skilled works. All the company is interconnected, maintaining the coherence.

Sivi Kontrol has a responsible commitment towards their personnel’s health & safety, the environment, and the material used. All jobs are planned in a way to avoid any risk.

To date, we have not suffered any accidents, neither personal nor environmental ones.

The low absenteeism level of our staff meets the company’s target for sickness absence rate below 2%. This low rate responds to the satisfaction level of our staff at work.

Every valve is subjected on routine base to different non-destructive testing, like the dye penetrant test on butt weld ends, on all hard faced and cladding areas.

Non-destructive tests are also carried out on the critical areas as defined by ASME b16.34.

Optional examinations like:

- Radiographic

- Magnetic particle

- Ultrasonic

- Helium leak test

Personnel performing NDT are trained and qualified to en 473/ ASNT-SNT-TC-1A.

Every valve is subject to a pressure test in accordance with the standard API 598 or BS 6755 Part.1. The rated pressure for the applicable pressure class is in accordance with ASME b16.34 and EN 12516-1/-2.

Each valve is identified on proper name plate and on valve body as required by MSS SP-25 and ASME b16.34. Name plate carries all information on rating, size, valve body and trims material, customer tags. On body, marking includes material designations (per ASTM) and heat code and of course the trade mark.