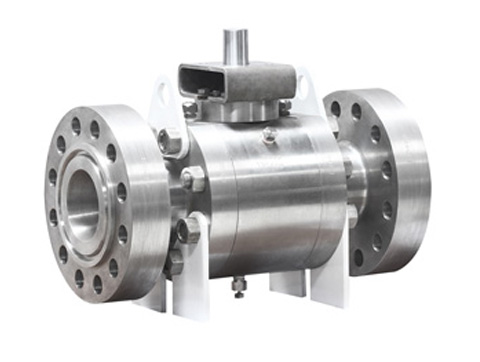

Features

- Emergency sealant injections – fitting prevents leakage from the stem

- Blow out proof stem – integrally inserted stem functions as the backseat for assured stem sealing at all pressures

- Emergency sealant injections – fitting prevents leakage from the seat

- Drain plug- relives the body cavity

- Double sealing o rings – prevents leakage from the stem area

- O ring and gasket combination – prevent leakage from the body joint area

- Floating springs- loaded seats assure sealing even at low pressure

- Metal to metal sealing – when soft seal are deteriorated by fire , seat float to shut off the line media.

Size & Pressure Class

- Cl 150 – 2” To 56” (Dn50 To Dn1400) Equivalne En / Din Standards

- Cl300 - 2” To 56” (Dn50 To Dn1400) Equivalne En / Din Standards

- Cl600 - 2” To 56” (Dn50 To Dn1400) Equivalne En / Din Standards

- Cl900- 2” To 36” (Dn50 To Dn900) Equivalne En / Din Standards

- Cl1500 - 2” To 24” (Dn50 To Dn600) Equivalne En / Din Standards

- Cl2500 - 2” To 12” (Dn50 To Dn300) Equivalne En / Din Standards

Reference Standards

- Design :- Api 6d / Asme B16.34

- Face To Face :- Api 6d / Asme B16.10

- Testing :- Api 6d / Api 598 / En-12266 / ISO -5208

- Fire Safe :- Api 607 / Api 6fa

- Antistatic Test :- Api 6d

- Cavity Relief Test :- Api 6d

- Mounting Dimensions :- Iso 5211

- Casting Inspection:- Mss Sp 53,54,55,59,93 & 94

- Forging Inspection:- Asme Section V Article 9

- Marking :- Mss Sp 25

- Radography Test :- Asme B16.34 In Accoedance To Asme Section V

- Ultrasonic Test ;- Asme B16.34 Annexure –E

- Magnetic Particle Test :- Asme B16.34 Annexure –C

- Low Temperature Impact Test :- Asme 370

- Nace :- Mr 01 75

- Fugitive Emmission :Iso-15848/Mesc-77/312

- End Connections:-

- Flnaged End: - Asme B16.5, Asme B16.47 , En 1092-1

- Buttweld End – Asme B16.25

Back to Ball Valves